Design

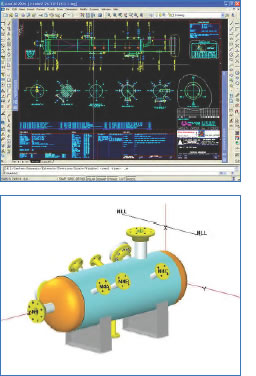

We had one of the UK's largest in-house mechanical design departments. Using the latest software available, our designers were constantly exploring ways to build and manufacture more efficiently.

Computer design software for the above codes included:

Design codes/standards

- PD5500

- ASME VIII (Div 1 & 2 plus holders of ASME U, U2, R and NB stamps)

- EN13445

- EN14015 (BS2654)

- API 650

- API 6A

- ASME B31.3

- DNV offshore rules

- NORSOK standards

- GOST plus SNIP standards

- NACE MR0175/ISO 15156

- PED 97/23/EC Compliance

Computer design software for the above codes included:

- Compress

- PV Elite

- Finglow

- Navisworks

- Caesar

- PMS

- StruCad

- AutoCad

We also offered Finite Element Analysis (FEA) of vessel components and structural steel design.

We held fully tested and certified WPS and PQRs to the above standards for welding the following materials:

We operated a fully audited

BSEN ISO 9001 quality control system to ensure quality standards are maintained and built into our products.

Draughting Capability

We had a fully trained drawing office that could supply full 2D or 3D AutoCAD fabrication drawings to suit your requirements.Welding Capability

- ASME IX

- BS EN ISO 15614

We held fully tested and certified WPS and PQRs to the above standards for welding the following materials:

- Carbon steels (inc SOUR service/HIC, SSC)

- Stainless steels - all grades

- Duplex and Super Duplex steels

- Hastelloy and Inconel high nickel alloys

- Low alloy steels

- Clad Carbon Steel Plates

Quality Assurance

We operated a fully audited BSEN ISO 9001 quality control system to ensure quality standards are maintained and built into our products.